Technology and Equipment Smoke and Mirrors

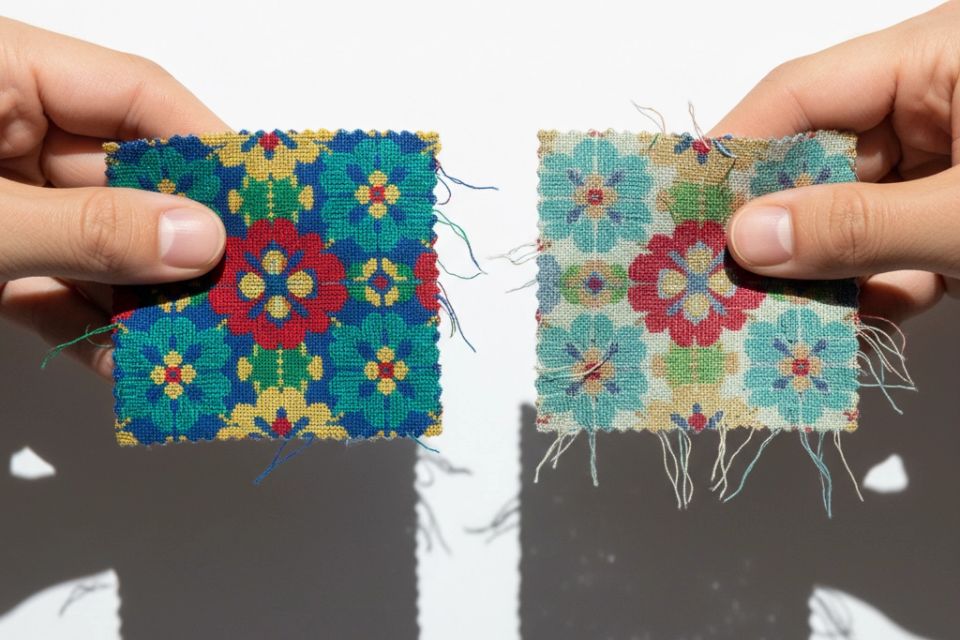

Suppliers love promoting their cutting-edge technology – CAD software, laser-cutting machines, direct-to-garment printers. The marketing materials showcase impressive equipment that makes everything look state-of-the-art and professional. But here's the reality check: equipment quality and operator expertise vary significantly.

Some manufacturers invest in impressive showroom equipment while using older, less precise machinery for actual production. It's like a restaurant with a beautiful dining room but a kitchen that hasn't been updated since the 1990s.

The real question isn't what equipment they own, but how they use it and maintain it. A well-maintained older machine operated by skilled technicians often produces better results than the latest technology in inexperienced hands.

What This Means for Your Business

Understanding these industry secrets fundamentally changes how you approach custom apparel sourcing. Success requires looking beyond surface-level marketing claims to understand the true capabilities and limitations of potential manufacturing partners.

The transparency gaps between marketing promises and production realities create opportunities for informed buyers to negotiate better terms, avoid common pitfalls, and build relationships with suppliers who value honesty over quick sales.

When you're evaluating potential partners for your custom apparel needs, remember that the cheapest option rarely delivers the best value.

Instead, focus on finding suppliers who demonstrate transparency, provide detailed quality control processes, and show flexibility in working with your specific requirements.

The custom apparel industry's secrets primarily revolve around information asymmetry – suppliers knowing things that customers don't. But now you're armed with insider knowledge that levels the playing field. Use it wisely, ask tough questions, and don't be afraid to walk away from suppliers who can't provide straight answers about their processes, capabilities, and quality standards.

Your brand deserves better than empty promises and hidden compromises. With these secrets revealed, you can make informed decisions that protect your investment and ensure your custom apparel truly represents the quality and professionalism your business demands.